Description

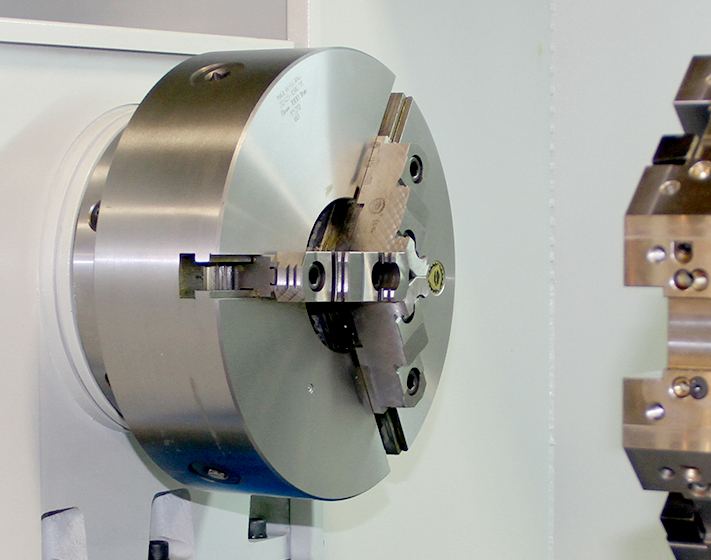

Summit 32″ SmartCut Flatbed CNC Lathe, SC32-10

Inventory # 8073

Model: SC32-10

Description:

The SmartCut Flatbed CNC Lathe Series from Summit is rugged and dependable. A combination of manual and CNC operation gives this series unbeatable precision for the finest finishes

SmartCut’s standard Fagor 8055TC controller is self-teaching. You can produce a part manually. Then with a few simple key strokes the controller stores the machining sequences and creates a part program. At a later time, retrieve the program. Enter the number of parts to be produced and SmartCut does the rest. The control language is conversational or G-code, with on-screen menus and prompts to make programming virtually foolproof

The power of the control features combined with manual hand wheels offers a variety of production applications. It enables you to use a single machine for one-off or prototype production, or set in a semi-automatic mode for small production lots, and in its fully-automatic mode for medium length production runs

Specifications:

Swing Over Bed: 31 1/2″

Distance Between Centers: 60″, 80″, 120″, or 160″

Swing Over Slide: 20″

Swing Over Gap: 43.3″

Hole Through Spindle: 9.8″

Spindle Speeds: 4 – 600 RPM (Variable)

Spindle Nose: A2-15

X-Axis Feed Rate: 0 – 250 RPM

Z-Axis Feed Rate: 0 – 400 RPM

Tailstock, Quill Diameter: 4.1″

Tailstock, Quill Travel: 10.8″

Motor: 30 HP

Standard Features:

Heavily ribbed cast bed and base

Hardened and precision ground bed ways

Precision ground ball screws

Infinitely variable speed ranges

Yaskawa spindle drive

Constant surface speed

Fine feed electronic hand wheels

Inch/metric capabilities

T-slotted cross slide for multiple accessory compatibility

Standard Equipment:

Steady Rest with Roller Tips

Follow Rest

Coolant System

Work Light

Sliding Enclosure Doors

Fagor 8055 CNC Control

Conversational or G-Code Programming

Communications via USB and ethernet

Versatility, it is a DRO when working manually; it is a motion controller when performing semi-automatic operation; it is a full-powered CNC control for automatic operation

Thread Repair Cycle

Mechanical Specifications:

Shipping Weight:

60″ Center Distance: approx. 9,900 lbs.

80″ Center Distance: approx. 11,000 lbs.

120″ Center Distance: approx. 13,200 lbs.

160″ Center Distance: approx. 15,400 lbs.

Contact us for special pricing and availability

FOB Factory