Description

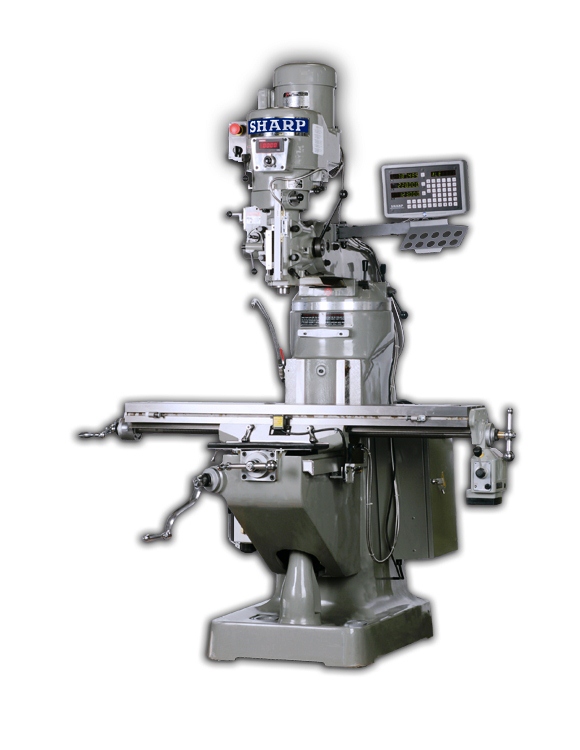

Sharp 10″ x 50″ Vertical Knee Mill Premium Package, TMV-K

Inventory # 2191

Model: TMV-K

Specifications:

Table:

Working Surface: 10″ x 50″

T-Slot Number, Size: 3, 5/8″

Capacity:

Table Travel (X-Axis): 35″

Saddle Travel (Y-Axis): 16.3″

Ram Travel: 18.5″

Quill Travel (Z-Axis): 5″

Knee Travel: 15.3″

Throat Distance (Min. – Max.): 9.8″ – 28.3″

Spindle Gage Line to Table Top: 1.6″- 16.9″

Spindle:

Motor: 3 HP

Wiring Voltage: 220v / 440v / 3ph

Taper: R-8

Speed (Vari-Speed): 60 – 4,500 RPM

Quill Feed (IPR): 0.0015, 0.003, and 0.005

Spindle Accuracy: 0.0002″ TIR

Head Tilt; Right to Left (Each Way): 90º

Head Tilt; Up-and-Down (Each Way): 45º

Standard Features:

Head:

Premium packaged TMV comes with power draw bar standard

Premium packaged TMV comes with 3 axes dro (quill, table & saddle) standard to achieve best accuracy, ease of use, and productibity

Premium packaged TMV comes with power feed table standard making your operation easier to manage

To dissipate heat in the 3 HP motor driven head, a pair of high output fans is installed. This allows the machine to work demanding jobs for extended periods without damaging the motor, belts and bearings

The motor shaft and vari drive pulleys are dynamically balanced, then hard-chromed. This allows a vibration free milling even at high speed

Since the vari-speed drive system is operated by sliding the vari drive pulley up and down the motor shaft. The motor shaft is therefore chrome-plated, and has an oil channel that is fed by a grease fitting on the lower end for self-lubricating purpose. This ensures the sliding motion is trouble free at all times

The motor shaft that drives the pulley and the spindle is subject to a lot of lateral stress. A roller bearing is installed for the lower support of the motor shaft

Beside swiveling 90° side to side, the head can also swivel up and down by virtue of a knuckle joint design. The new design developed by sharp uses 6 bolts, 3 on each side, that fitted into a circular t-slot milled at the inside of the over arm and secured by nuts from the outside. It secured the head tightly and offered high accuracy in milling operations

A matched pair of super-precision ABEC-7 angular contact bearings supports the spindle. The quill is CNC-Ground to a mirror finish, and then chromed to fit the housing. Together, they insure spindle run out of no more than 0.00002″ TIR – the best in the industry

Column, Table and Knee:

Hardened and ground box ways on column and saddle

Turcite coated slideways for better resistance to wear and retention of lube oil

Certified meehanite castings are used for superior rigidity and better dampening of vibrations

Table and saddle backlash is controlled by a double-nut design that keeps the feed screw in contact with a pair of bronze nut at all times

Hardened leadscrews on table and saddle for better resistance to wear

The end of the table and saddle are mounted with thrust bearings that pre-load the feed screw, eliminating endplay for precisely controlled lateral movement

Instead of hand scraping the top of the knee ways for oil retention, the matching underside of the saddle is hand-scraped. This extra step avoids having chips and dirt embedded in the knee ways and damages the sliding area

Standard Accessories:

Hardened and ground box ways

Power draw bar

3 axes DRO (quill, table and saddle)

Power feed table

Front and rear way cover

One-shot lube system

Toolbox with tools

Optional Accessories:

Power Feed System on Saddle and Knee

Riser Block (4″ or 7″)

Right Angle Milling Attachment

Coolant System with Chip Pan

Milling Vise

Clamping Kit

Halogen Work Light

R-8 Collets

Mechanical Specifications:

Dimensions: 70″ W x 75″ Deep x 88″ H

Weight: approx. 3,000 lbs.

Contact us for special pricing and availability

FOB Factory