Description

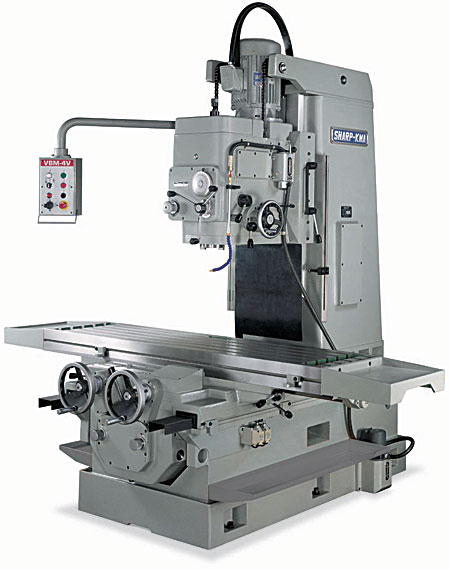

Sharp 15″ x 40″ Heavy Duty Bed-Type Vertical Mill

Inventory # 2240

Model: KMA-1

Specifications:

Capacity:

Table Travel (X-Axis): 39 3/8″

Table Travel (Y-Axis): 14 15/16″

Spindle Head Travel (Z-Axis): 19 11/16″

Spindle Nose to Table Top: 3 15/16″ – 23 5/8″

Spindle Center to Column Front: 14 15/16″

Table:

Table Working Area: 67″ x 14 15/16″

T-Slot: 0.75″ W x 5 x 2 3/4″ Pitch

Table Top to Floor: 31 1/2″

Max. Loading Weight: 1,760 lbs.

Spindle Head:

Spindle Nose: # 50

Spindle Speeds: 45 – 1,500 RPM (12 Steps)

Vertical Feeds: 0.002 – 0.008 IPM

Feeds:

Rapid Traverse (X,Y): 113 3/8″ IPM

Feeds (X,Y): 1 1/8″ – 34 7/16″ IPM

No. of Feeds: 12 Steps

Motors:

Spindle: 10 HP

Speed: 1 HP

Coolant Pump: 1/8 HP

Electrical: 220v, 440v / 3ph

Standard Features:

ISO 9002 Certified Factory: Quality up to world industry standards

Certified Meehanite Casting: Highest grade of casting possible

Boring Capability: The full length travel of the vertical head along with 6 different feeds offer capability for precise boring operation

Electro-Magnetic Spindle Control: The spindle is equipped with electric power brake for instant clamping of spindle. It also has forward/reverse switch for tapping operation and spindle jog motion for proper tool holder engagement

Hardened and Ground Gears: The gearbox inside the spindle head and the table feed mechanism utilize hardened and ground gears for long lasting wear. The spindle head gearbox is equipped with an automatic lubrication system. The table feed gearbox has an oil splash system for lubrication

Pendant Style Operation Panel: The pendant control panel allows easy operation of all power driven mechanism, electrical, pneumatic or hydraulic. It has a toggle style control for 4-way feed and rapid traverse of the table

Auto Lube Table and Saddle Ways: The slideways upon which the saddle and table travel, are automatically lubricated when the machine is turned on

Hardened and Ground Boxways: The C frame construction offers the best machining capability for heavy milling and boring applications. By using hardened and ground durable box ways in the Z-Axis, significant rigidity is given to the cutting head. The saddle is also mounted on two massive hardened and ground body ways for maximum stability during heavy cutting

Honey Combed Ribbing: The vertical column is made out of box-shaped, high-quality, gray iron castings. It is reinforced with honeycombed ribbing, instead of the usual rectangular ribbing, which is 70% more effective in dampening vibration and sustaining mechanical and thermal stability

Table and Saddle: High quality castings used on the table and saddle are stress releived to avoid any slight distortion in the future and the sliding surfaces are hand scraped to ensure full bearing and support and to achieve high accuracy in machining. All top, front, rear reference surfaces and T-slots are precision ground to exact tolerances

Adjustable Backlash Eliminator: A double-nut construction eliminates backlash between the net and lead screw that drives the table, this allows accurate movement of the work piece during machining. As time goes, there will be wearing on the nut creating backlash, the double nuts can be adjusted to take out the additonal backlash. Precisely milled oil groves on top of the saddle ensured adequate lubrication between the table and the saddle

Unique Sliding Saddle Base Design: To allow easy access to the work piece for inspection or positioning, the entire saddle base can slide in and out from the operator manually or by power feed. This feature is particularly convenient considering the cross movement of the saddle can reach up to 23″

Eye Level Vertical Head Control: The large spindle head offers manual coarse and fine in addition to power feed for positioning of the head. Controls for these feeds together with spindle speeds and the head locking mechanism are all mounted at eye level on the spindle head casting. The tri-lever rotating manual rapid feeds mounted at the front allowing quick positioning of the head for machining

Standard Equipment:

Auto lubrication system

Leveling blocks (6 Pieces)

Leveling nuts and bolts – 6 sets

Draw – in Bolt (1 Pieces)

Coolant System

Tool Kit includes: Machine manual half nut wrench (17m & 19m), set of 6 Allen Wrenches, Philip Screw Driver, Flat Head Screw Driver, Oil Can, Grease Gun, Rear Way Cover Bracket, Pin for Indicator and Can of Paint

Optional Accessories:

Digital Read Out

Halogen Work Light

Power Draw Bar

Mechanical Specifications:

Dimensions: 126″ x 78 3/4″ x 94 7/8″ H

Weight: 9,000 lbs.

Contact us for special pricing and availability

FOB Factory