Description

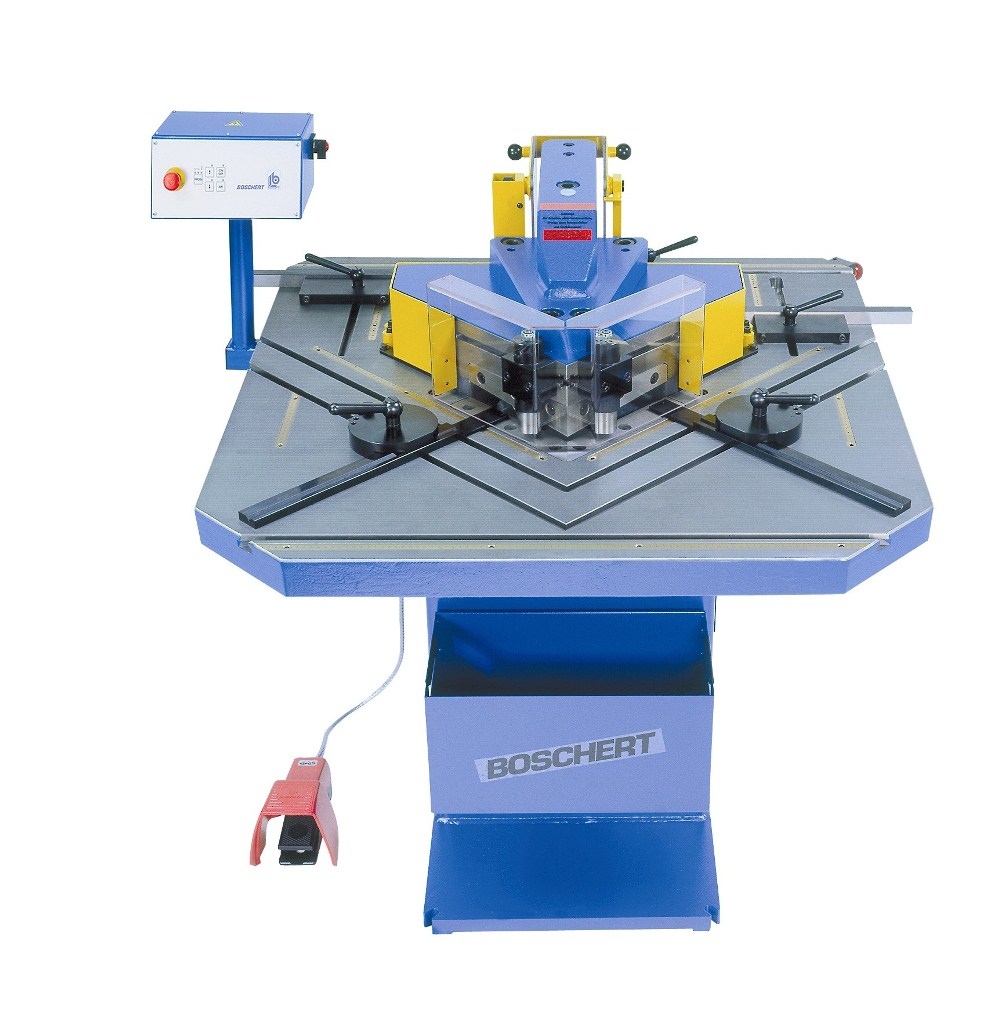

Boschert 1/4″ Silver Eagle Quick Hydraulic Notcher

Inventory # 6190

Model: Silver Eagle Quick

Specifications:

Cutting Capacity: 1/4″, Mild Steel

Cut Length: 8 7/8″ x 8 7/8″

Cut Angle: 90°

Notching Station:

Capacity:

Mild Steel: 1/4″

Stainless Steel: 5/32″

90° Notch: 8 7/8″ x 8 7/8″

Table Dimensions: 43″ x 44 1/2″

Second Station: 1″ x 4″, 15° – 45° x 4″

Motor: 6.5 HP / 220v / 3ph

Standard Features:

Super Size Table, 43″ x 31″ Deep

Milled bed surface for no float or stick operation

Moveable electrical foot pedal

Front to back cutting to hold material against stop

Adjustable stroke, 35 – 50 per minute

Two material hold downs

Two heavy duty stops with 12″ sliding bars

Scale and T-slot left to right at front of bed

Scale and T-slot parallel to the blades

Scale on left and right side of table top

Internal stop for shearing

Scrap bucket

Second station for coping, punching or notching, a quick change system for the second station with the blades mounted in a cassette with the correct clearance pre-set. Cassettes for coping, punch tools and small notches are available

Length of cut from 0.1″ – 1.18″

3/16″ mild steel capacity, 12 gauge stainless steel capacity

Trumpf style punch and die, size I

Boschert Patented Quality:

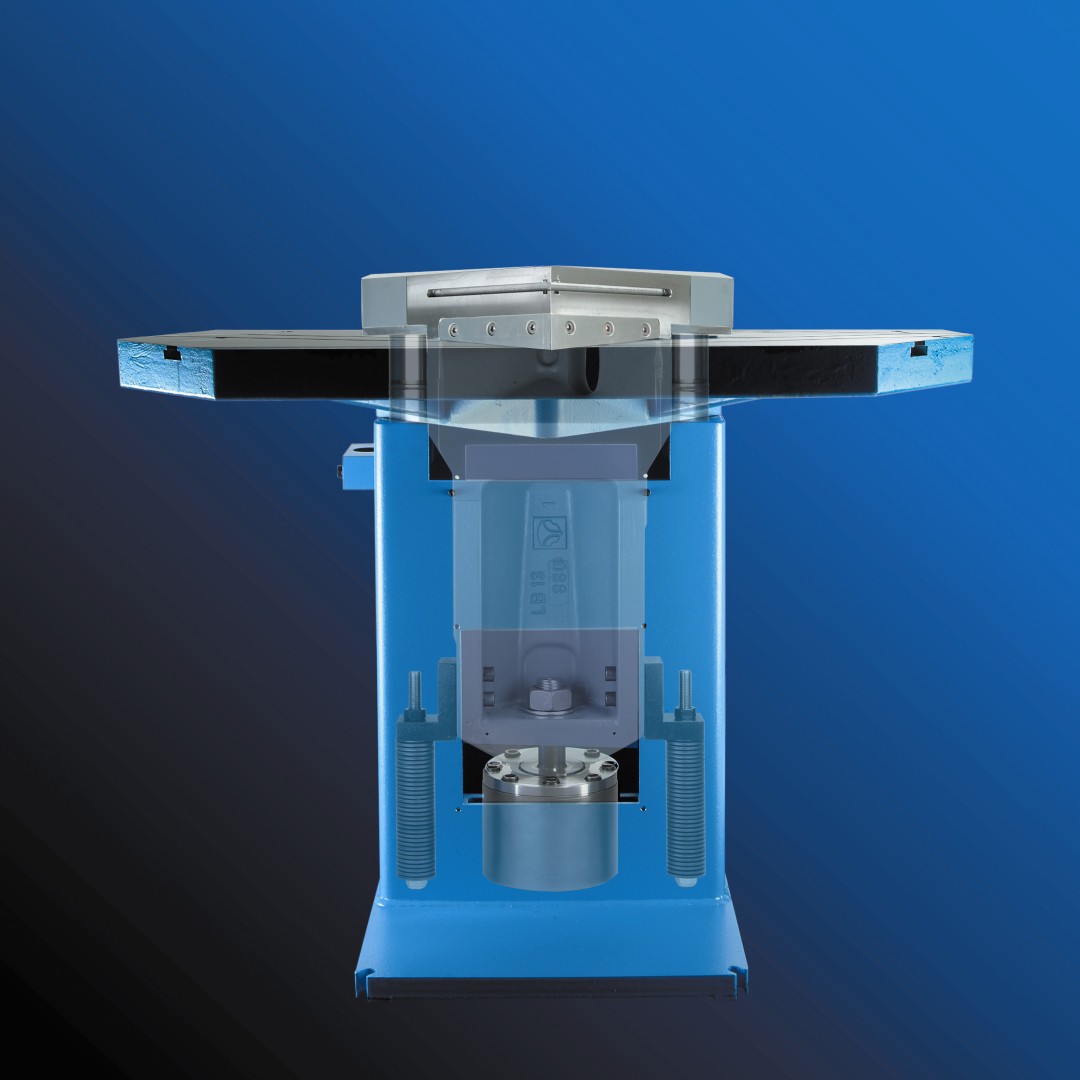

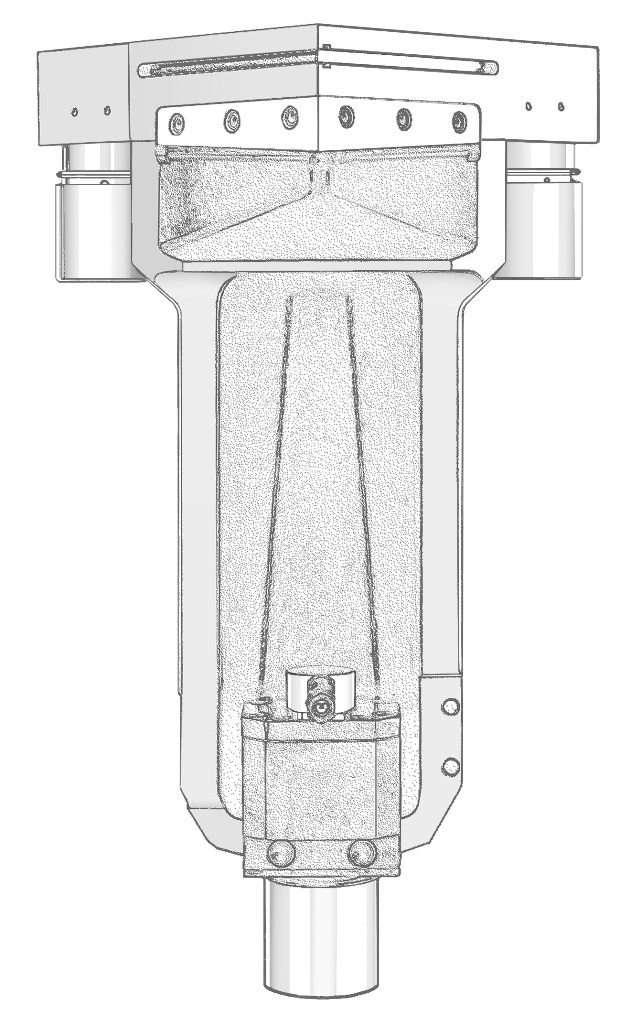

The patented Tri-Gide system gives all Boschert notching machines the greatesr accuracy and durability of any notcher made today

“Tri” is for the three large guiding cylinders. Two cylinders are in the top of the machine, close to the blades, the third is in the base and fully integrated with the hydrailic piston

“Gide” is for the precise vertical travel of the arm. Torque from cutting heavy material is distributed evenly to all three cylinders

Exclusive Tri-Gide Benefits:

Long blade life due to precise, rigid ram guiding

Burr-free cuts on all gauges (within capacity)

Off-center loading is not a problem

Trouble-free self-lubricating system

Absolute clean cut

5-year warranty on the guiding system

Maintenance free

Other Features of all Boschert Notchers:

Inclined blades cutting from front to back, ideal for cutting to a scribe line, no displacement of the material

Heavy construction using a 1″ thick base plate welded solidly to heavy 5/8″ thick side plates on all sides

Single stroke, continuous and set-up operating modes

Overload protection

Simple handling of the material stops

Patented hold-down material stops

Mechanical Specifications:

Dimensions: 53″ x 43″ x 50″ H

Weight: approx. 2,420 lbs.

Contact us for special pricing and availability

FOB Factory