Description

Micro Air ‘TaskMaster’ Air Cleaner/Dust Collector, TM1000

Inventory # 9504

Model: TM1000

Typical Applications:

Weld Smoke and Fumes

Grinding Dust

Particulate from Buffing/Polishing

Dry Particulate

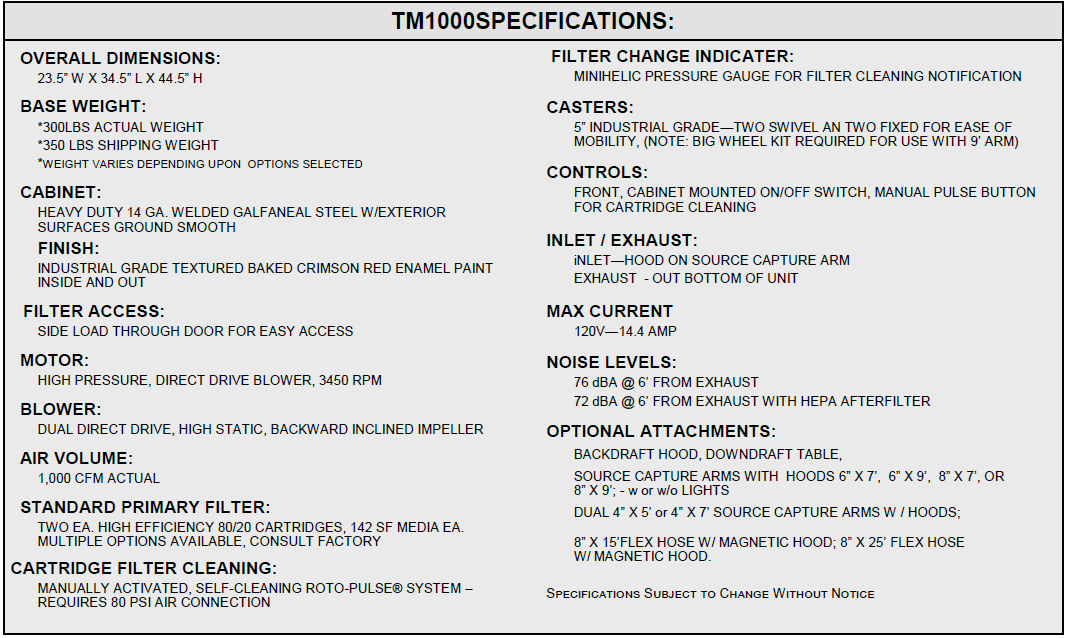

Specifications:

Overall Dimensions: 23 1/2″ x 34 1/2″ x 44 1/2″ H

Cabinet: Heavy Duty 14 Gauge Welded Galfaneal Steel with Exterior Surfaces Ground Smooth

Finish: Industrial Grade Textured Baked Crimson Red Enamel Paint Inside and Out

Filter Access: Side Load Through Door for Easy Access

Motor: High-Pressure, Direct-Drive Blower, 3,450 RPM

Blower: Dual Direct-Drive, High-Static, Backward Inclined Impeller

Air Volume: 1,000 CFM

Standard Primary Filter: (2) High-Efficiency 80/20 Cartridges, 142 SF Media (Multiple Options Available)

Cartridge Filter Cleaning: Manually Activated, Self-Cleaning Roto-Pulse System – Requires 80 PSI Air Connection

Filter Change Indicator: Minihelic Pressure Gauge for Filter Cleaning Notification

Casters: 5″ Industrial Grade – Two Swivel and Two Fixed for Ease of Mobility (Note: Big Wheel Kit Required for Use with 9′ Arm)

Controls: Front, Cabinet Mounted On/Off Switch, Manual Pulse Button for Cartridge Cleaning

Inlet/Exhaust: Inlet, Hood on Source Capture Arm – Exhaust, Out of Bottom of Unit

Max. Current: 120v – 14.4 Amp

Noise Levels: 76 dBA @ 6′ from Exhaust – 72 dBA @ 6′ from Exhaust with HEPA Afterfilter

Standard Features:

Dual Self-Cleaning Cartridges

High Capacity Cleaning

Compact Design

Wide Range of Filter Options

Low Power Requirements – 120v, Single Phase

Improved Source Capture Arm – Designed for Ease of Movement, Less Restriction and Powerful Collection at the Source

Roto-Pulse Cartridge Cleaning System

How It Works:

Contaminated air is pulled into the hood on the source capture arm, then, travels down through the cartridge section, where the contaminant is filtered out and dropped into the dust drawer at the bottom of the unit. Clean, safe air is exhausted from the bottom of the unit. Cartridge cleaning is accomplished with Micro Air’s, proprietary Roto-Pulse cleaning system where the air is pulled into a specially designed stainless steel rotating tube, engineered with pre-drilled holes

As the air enters this tube the force of the pulse causes the tube to rotate inside the cartridge. While spinning, air exits the pre-drilled holes, resulting in air dispersement over the entire surface of the cartridge, providing for a more efficient cartridge cleaning cycle

Options:

Broad Choice of Attachments to Adapt to Any Application or Process:

Backdraft Hood, Downdraft Table

Source Capture Arms with Hoods – 6″ x 7′, 6″ x 9′, 8″ x 7′, or 8″ x 9′ – with or without Lights

Dual 4″ x 5′ or 4″ x 7′ Source Capture Arms with Hoods

8″ x 15′ Flex Hose with Magnetic Hood; 8″ x 25′ Flex Hose with Magnetic Hood

2 HP, 208v/230v, 3-Phase Motor

2 HP, 460v, 3-Phase Motor

Auto-Pulse Cartridge Cleaning

99.97% HEPA Afterfilter

Refillable Charcoal Modul

Multiple Arm Diameter / Length Combinations

Big Wheel Kit (Required with 8″ x 9′ Arm Option)

Contact us to Discuss Options and Pricing

FOB Factory