Description

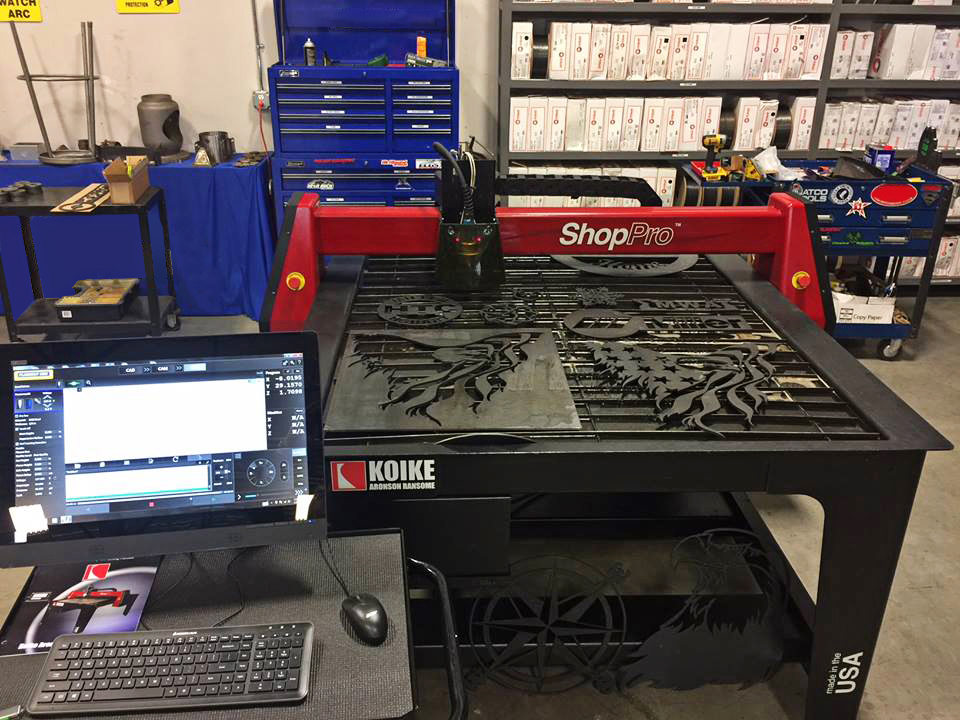

Koike Aronson ShopPro CNC Plasma Cutting Machine

Inventory # 7442

Model: ShopPro

Koike ShopPro CNC Plasma Cutter Featured Article in Modern Metals Magazine

Specifications:

Table Sizes Available:

4′ x 4′

4′ x 8′

5′ x 10′

Table Capacity: 2″ (Mild Steel)

Tool Capacity: 2

Control Voltage: 115v / 1ph

CNC Controller: FlashCut CNC 21* Panel PC

Drive System: Stepper

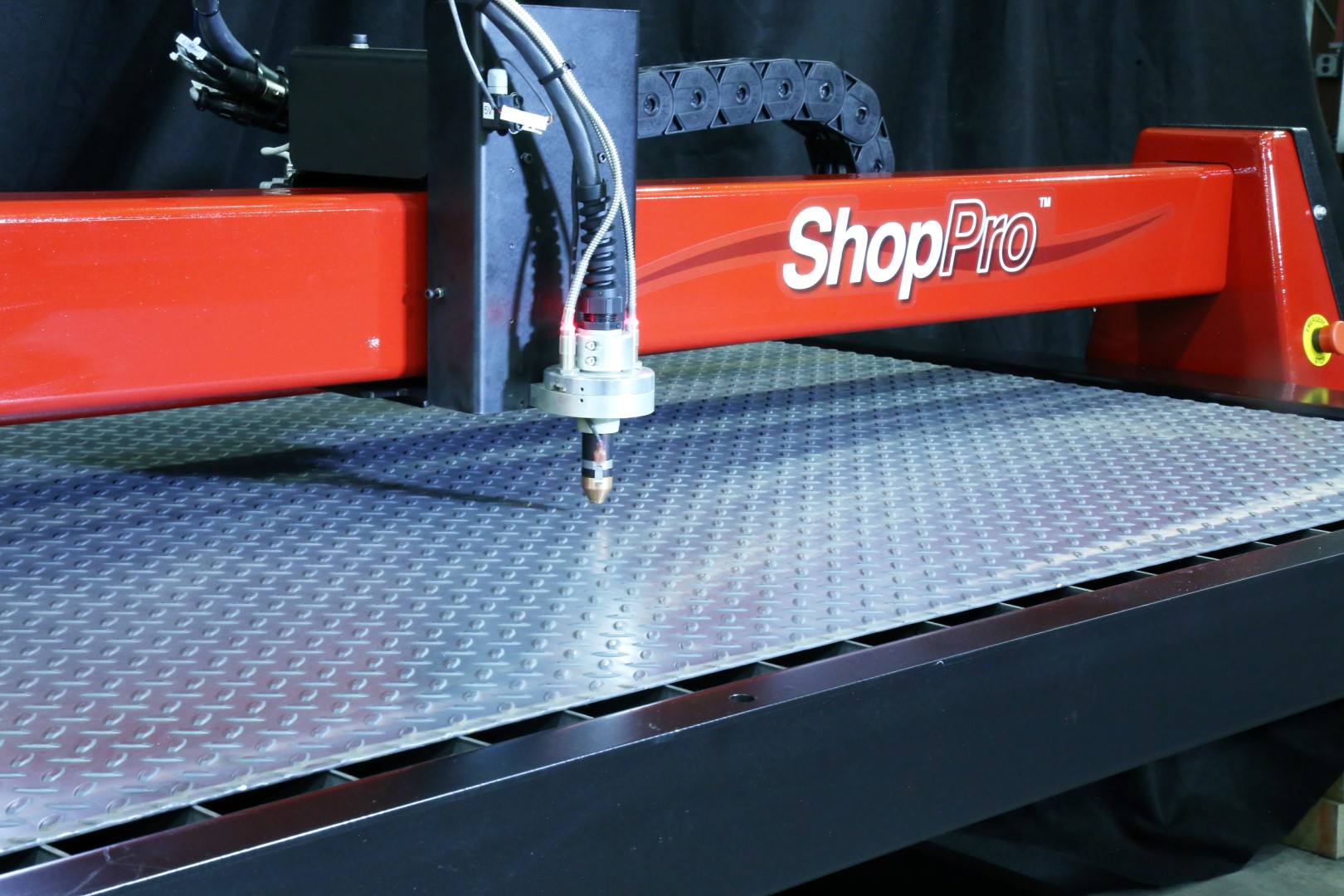

Table Type: Water Pan Insert

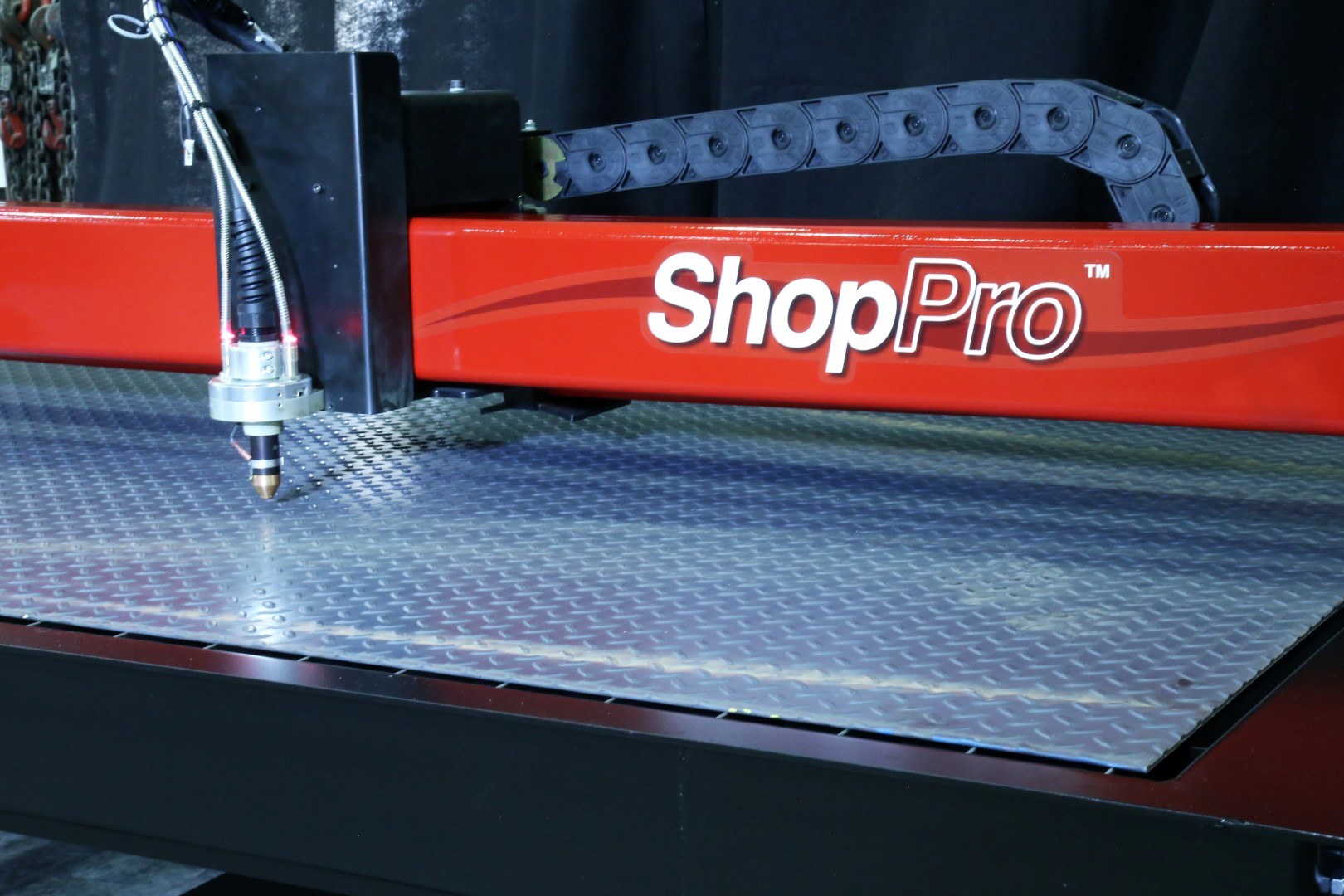

Rack and Pinion Drive System:

Stepper Motors: (3) 954 oz-in NEMA-34

Gear Reduction: (3) Precision Helical | O: | gearboxes

Linear Guidance: 22 mm Profile Linear Rail, 30 mm Gantry

Gear Engagement: Direct Drive Helical Rack and Pinion

Gantry Carriage: Solid Steel Construction

Traverse Speed: 1000 IPM

Machine Repeatability: 0.0015″

Frame Construction: 7 Gauge (Mild Steel)

FlashCut CNC All-in-One Motion Controller and 21″ Panel PC:

Adjustable PC mount with acces to all connections reducing exposed cabling on machine

Integrated plasma torch height control follows the sheet surface at the precise height

Real time visualization of toolpath and torch voltage settings

Completely integrated FlashCut CAD/CAM/CNC enables you to easily draw a 2D part, create the toolpath with lead-ins and outs, nest and cut

DXF import, image import and shape library with a multitude of menu driven shapes

Integrated cut charts for plasma

Automatic kerf crossing detection in THC algorithm prevents unwanted diving

On-board completely integrated FlashCut 2D

CAD/CAM package

Plasma support interface

Oxy-fuel support interface

DXF/DWG import / silhouette import

Standard grid nesting

On-board automatic trueshape nesting software

Enhanced production nesting features – fill sheet, multi sheet, partial sheet, on-board lead-in and lead-out type, positioning and length adjustment

Customizable plasma cut charts for hypertherm

Smart feedrate and THC handling of small holes

Overburn support

Automatic cut settings based on material

Automatic kerf compensation

Easy CNC program flow control including jump to line

Forward and reverse processing

Fix tool finds and corrects CAD mistakes instantly

Commonly used plate list

Tabbing support

Assign different operations to each part

Cut sequencing

Operation sequencing

Drag, delete, rotate and copy parts on nest

Cutout or part mode

Cutom views of kerf width, cut direction, toolpath, rapids and part geometry

Customizable poet processor

Kerf corssing detection

Dry and momentary run

Remote diagnostics

Contact us for special pricing and availability

FOB Factory