Description

Koike Aronson Portable Welding and Gas/Plasma Cutting Machine, IK-12 NEXT

Inventory # 8691

Model: IK-12 NEXT

Description:

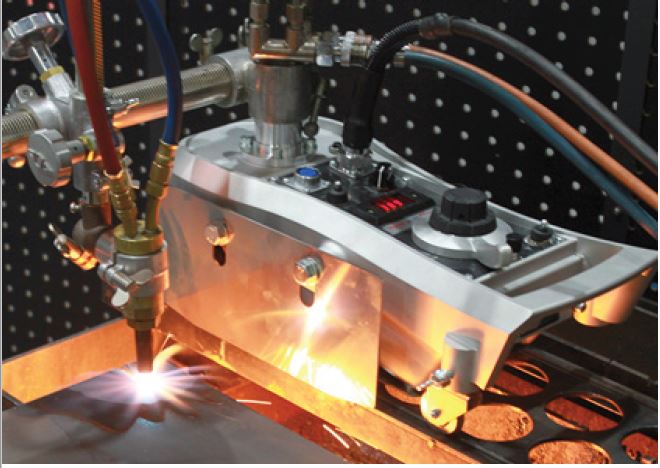

Designed to replace the rugged IK-12 Max3, one of the most popular and longest selling cutting carriages in the fabrication industry

The IK-12 NEXT is an incredibly strong, versatile tractor that is specifically designed to be compatible with most applications. With the ability to adapt to each process, the machine is versatile but still retains a simplistic operating system

Standard Features:

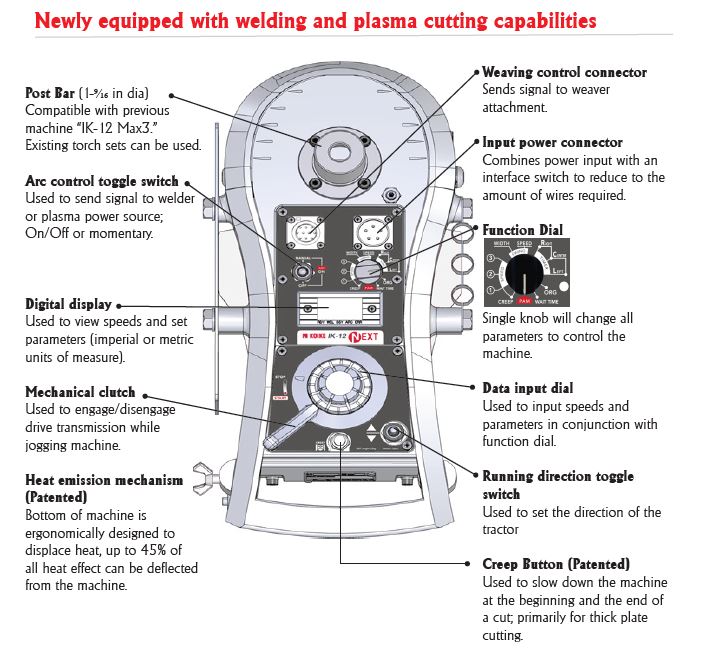

Multi-Function Control Panel: The new digital control panel enables the operator to accurately set a wide range of parameters as they relate to each process. With the use of a LCD display, set-up time is greatly reduced and made more repeatable

Powertrain: Allows for extremely accurate positioning and ensures continuous drive speed and pulling force that is not compromised by power fluctuations or varying load weight

Multi-Purpose Cutting and Welding: The machine comes standard with the ability to interface to most power sources. Whether cutting or welding, the IK-12 NEXT has a built-in control that will send command signals directly to an attached power source interlock switch

Torch Sets – Oxy-Fuel Cutting Torch Sets:

S-100 Torch Set:

– Standard 1 torch unit

– Single torch head commonly used for plate stripping or performing compound bevel work

S-200 Torch Set:

– Standard 2 torch unit

– Dual torch head commonly used for plate stripping and performing compound bevel work

SP-100 Torch Set:

– 1 torch unit with mechanical torch height control

– Allows same functions as above, but includes a plate tracking system used to maintain accurate plate distance from workpiece. Allows for more accurate beveling

SP-200 Torch Set:

– 2 torch unit with mechanical torch height control on each torch unit

– Allows same functions as S-200, but includes a plate tracking system used to maintain accurate plate distance from workpiece. Allows for more accurate beveling

SP-300 Torch Set:

– 2 torch unit iwth mechanical torch height control on a single tracking system

– Commonly used for V-grooves or plate edge beveling

– Maintains angle of 2 torches for accurate Y and X bevel cuts

SP-400 Torch Set:

– Triple torch on a single tracking system. Commonly used for maintaining angle of three torches for accurate Y, X, and K bevel cuts

– Used for heavy plate beveling

300L Heavy-Duty Torch Kit:

– Heavy duty torch designed to cut up to 10″ plate thickness or where a large stand-off is needed

Welding – Torch Set for Butt Welding:

A Type Welding Holder Set:

– A single torch clamp that will give torch angle and tilt in all directions

– Allows torch to tilt +/- 45° for easy and accurate positioning

Pendulum Weaver:

– Weaving unit increasing welding deposition with fewer passed. Numerical control for swing width and speed

FOB Factory