Description

Ercolina 4″ x 1/2″ Hydraulic Programmable Angle Roll-Section Bender with 3-Axis Twist Correction

Inventory #7455

Model: CE100H3-RLI

Specifications:

Pipe (Max.): 4″ Sch. 40

Angle (Max.): 4″ x 4″ x 1/2″

Tube (Max.): 4 1/2″ – .237 wall

Roll Shaft Diameter: 100mm

Center Roll Positioning: 30 Tons Hydraulic

Shaft Speed: 6 RPM

Universal Tooling (Included): 12 5/8″O.D.

Programming: NC – Touchpad

Number of Programs: 8

Distance between Shafts: 19 1/4″

Section Modulus: 90 cm

Voltage: 220v, 480v / 3ph

Standard Features:

Universal tooling set included with each machine

Forged roll shafts precision ground and fitted for maximum performance and minimal deflection

Roll shafts supported with conical steel bearings on each side of A Frame

Heavy duty structure and rigid components for high section modulus ratings

Reinforced engineered mainframe design proven to outperform competitive models

In-line direct drive roll shaft system with motor and brake on each shaft

Threaded roll shafts with micrometric flange adjustment helps eliminate spacer usage

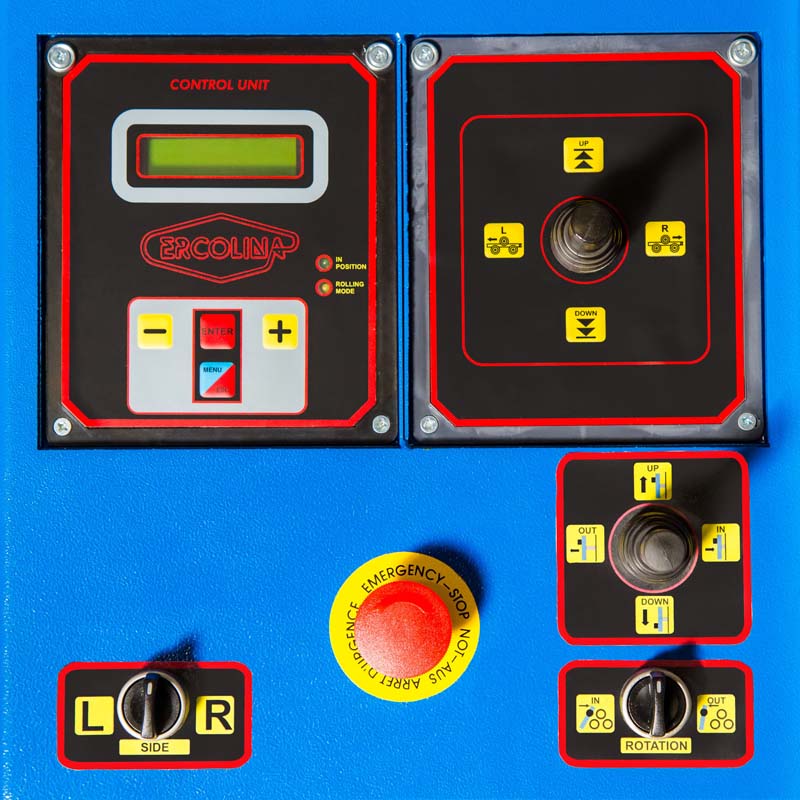

Touchpad controls with digital center roll positioning

Control tower with low voltage controls and foot pedal

Memory storage has eight (8) individual programs and unlimited passes

Three axis hydraulic twist correction system for angle iron “Leg-in” applications

Mechanical Specifications:

Dimensions: 66″ x 58″ x 83″ H

Weight: approx. 5,550 lbs.

FOB Factory