Description

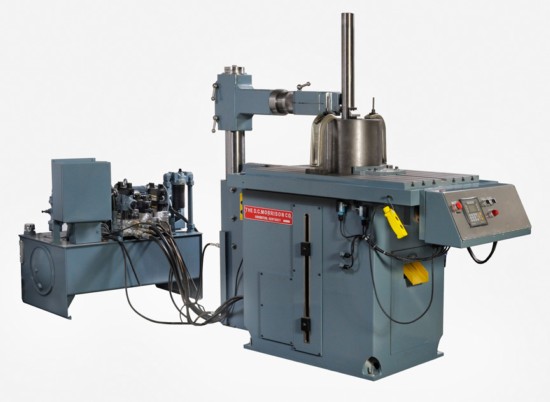

D.C. Morrison 3″ N.C. Keyseater

Inventory # 8337

Model: N.C. Keyseater

Made in USA

Description:

The newly redesigned Morrison 3″ Keyseater has been physically modified and is more rigid than ever! The back support

bracket is twice the length of the older models, enabling more accurate keyways in various materials

The overhead support is now easily raised and lowered by hydraulics with the push of a button. The programming is now

extremely user friendly with the use of a programmable logic controller and human machine interface (HMI)

As in the past, the Morrison Keyseater does not require to be positioned in a pit, and needs no bushings to center the

keyways. Cuts from 1/8″ to 3″ wide and 14″ high

Specifications:

Cuts Keyways: 1/8″ – 3″

Max. Length of Cut: 14″

Number of Feeds: (6) .001″ – .006″

Distance from 2″ Cutter to Column: 34 1/2″

Table Size: 50″ x 36 1/2″

Table Height from Floor: 41 1/2″

Motor: 20 HP / 220v, 440v / 3ph

Standard Features:

Automatic Feed: Automatic feed eliminates pushing a feed bar, eliminates the human error of feeding too much or too little.

The automatic feed ensures accuracy and enables the operator to get ready for the next set-up

Automatic Stop: Automatic stop automatically cuts off the feed for any given depth and this also frees the operator for

other duties

Automatic Relief: Automatic relief backs the work away from the cutter on the up stroke eliminating drag and ensuring a

clean keyseat

Quick Set-Up: Quick set-up is one of the most important features. The operator has all control handles built into the

machine and to change from one piece to another is very simple, and requires the least amount of time. Also different

cutter bits are interchangeable. The cutter bar does not need to be changed in order to cut different keyseats

Uses Single Tooth Cutters: Single tooth cutters are not only for accuracy but eliminate time and trouble in sharpening. All cutters

are of the finest high speed tool steel

Adjustable Stroke: The stroke is infinitely adjustable. This is very desirable when slower cutting speeds are required

Automatic Centering: Automatic centering centers up the work quickly and easily. It can be set for multiple jobs of two or

more pieces, automatically centering the next work piece

Automatic Lubrication: Automatic lubrication feeds oil to all necessary moving parts by the means of a “one shot” system

convenient to the operator

Uses No Bushings: Uses no bushings and this feature not only simplifies the operation but no extra equipment need to be

ordered to cut a keyseat in any size bore. The cutter bar is supported close to the actual cut by a quick acting, adjustable,

cutter bar support, both above and below the work

Hydraulic System: With the hydraulic set on maximum pressure cylinder size is 3 1/4″ diameter. The machine will develop

approximately 8 tons of cutting pressure at cutting edge of cutter

Mechanical Specifications:

Floor Space Hydraulic System: 41″ x 43″

Floor Space Keyseater: 84″ x 36″

FOB Factory

Please Note: Extended Lead-Time Estimated 12 to 18 Months